Saint-Gobain

Saint-Gobain

Sustaining Member of the Month - March 2017

Saint-Gobain

Ceramics for Body, Vehicle and Aircraft Armor

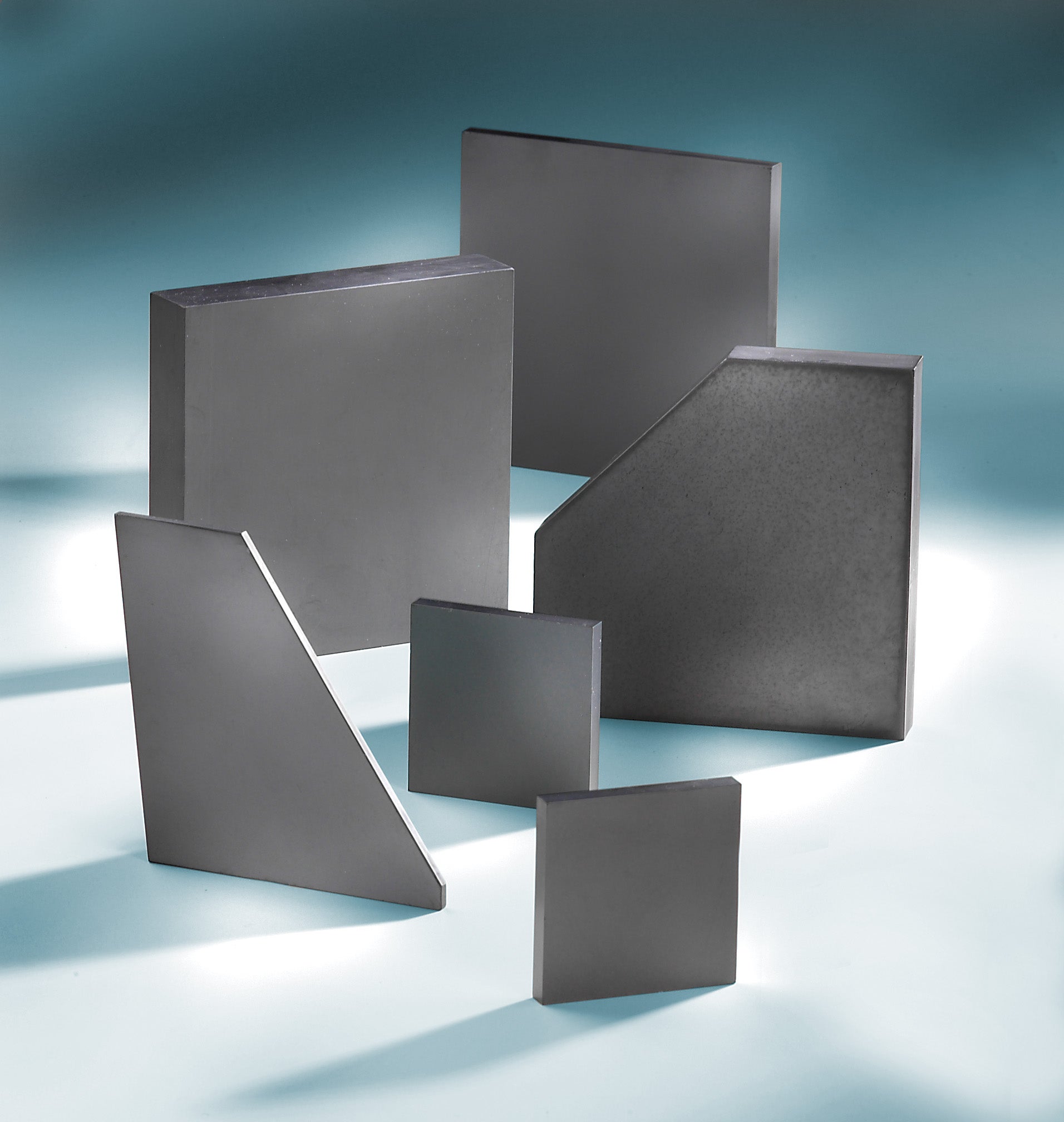

Saint-Gobain Engineered Ceramics offers a broad range of ceramic materials as the strike face in composite armor protection systems, including silicon carbide (SiC), boron carbide and alumina. The properties of these materials — high hardness, fracture toughness, compressive strength and elastic modulus — provide superior ballistic capability to help defeat high-velocity projectiles.

With a long and proud history of protecting the American warfighter, Saint-Gobain Engineered Ceramics has provided personal ceramic armor since the 1960s, including the first true ceramic body armor system. In fact, we manufactured 70,000 plates of ceramic body armor to protect U.S. troops in Vietnam.

In addition to personal protection ceramic armor, Saint-Gobain Engineered Ceramics manufactures ceramic armor for vehicular, aircraft and other ballistic protection applications. It has provided sintered SiC for the armor systems of all U.S. Department of Defense fleets of AC-130U gunships and for many of the C130, C17, C5 and C141 transport planes.

With a high-volume capacity to produce extremely complex shapes for a variety of ballistic protection applications, Saint-Gobain Engineered Ceramics is a vertically integrated supplier — a reliable source of products ranging from powder to the finished sintered alpha SiC ceramic armor part — with an innovative product line that includes:

- Hexoloy® SA, an SiC grade that features high hardness, compressive strength and light weight

- Hexoloy® SB, an SiC grade that features high hardness, compressive strength and ultra-light weight

- Hexoloy® CG, an SiC grade that features high hardness, improved fracture toughness and light weight

- Forceram, SiC that features light weight and good fracture toughness

- Norbide®, boron carbide that features high hardness, low density and low weight

- Crystar®, SiC that features good strength and oxidation resistance

- Silit® SKDH, SiC that features high modulus and high sonic velocity

Technical Production and Development Efforts

The business continues to participate on numerous ceramic armor programs that have supplied SiC ceramic plates and tiles to many higher-tier integrators, including directly to the United States Army. Other key facts include:

- In 1996, Saint-Gobain acquired the Carborundum Company, which invented SiC in 1891. Crude SiC continues to be produced to this day by the Acheson process, which is named after Carborundum’s founder William Acheson.

- Carborundum invented the pressureless sintered version of alpha SiC in the late 1970s (trademarked as Hexoloy® SA SiC).

- Saint-Gobain Engineered Ceramics has since developed several variants of Hexoloy SiC to balance performance, weight and cost, including the newest, lightweight SB product.

- Saint-Gobain Engineered Ceramics is the world’s leading producer of crude SiC of suitable quality (green) for sintered alpha SiC ceramic armor.

- Saint-Gobain Engineered Ceramics produces its own ready-to-press (RTP) Hexoloy SiC powder in Niagara Falls, New York. This RTP powder is made from crude green SiC sourced from Saint-Gobain in Norway, a NATO country.

Saint-Gobain Engineered Ceramics is part of Saint-Gobain High-Performance Materials, which has sales in excess of $4 billion and more than 27,000 employees. Saint-Gobain Corporation had gross sales in excess of $43 billion in 2015 and more than 170,000 employees.

Learn more about our offer to the Defense and Security market and Contact us for any specific topic you would like to discuss with us.