Advanced Cooling Technologies, Inc

Advanced Cooling Technologies, Inc

Advanced Cooling Technologies, Inc. (ACT) is a premier thermal management solutions company operating out of two locations in central Pennsylvania. Founded in 2003, ACT began as a research and development company; today, R&D continues to serve as a tenet of ACT’s philosophy. Innovative technologies developed by ACT engineers are utilized in thermal management systems for a diverse set of markets, including Defense, Aerospace, Spacecraft, Electronics, Energy Recovery, Medical, Enclosure Cooling, and Calibration Equipment. As a result, ACT recently surpassed $100 million in commercialized product sales with Small Business Innovative Research (SBIR) technologies.

While certain off-the-shelf components are available from ACT (namely its sealed enclosure coolers and ICE-Lok® wedgelocks), the company specializes in advanced, custom solutions that are tailored to meet the unique project requirements of its customers. ACT’s core values of Innovation, Teamwork, and Customer care are manifested in its design process wherein ACT engineers collaborate with their customers to develop the most efficient and effective solutions for their diverse needs.

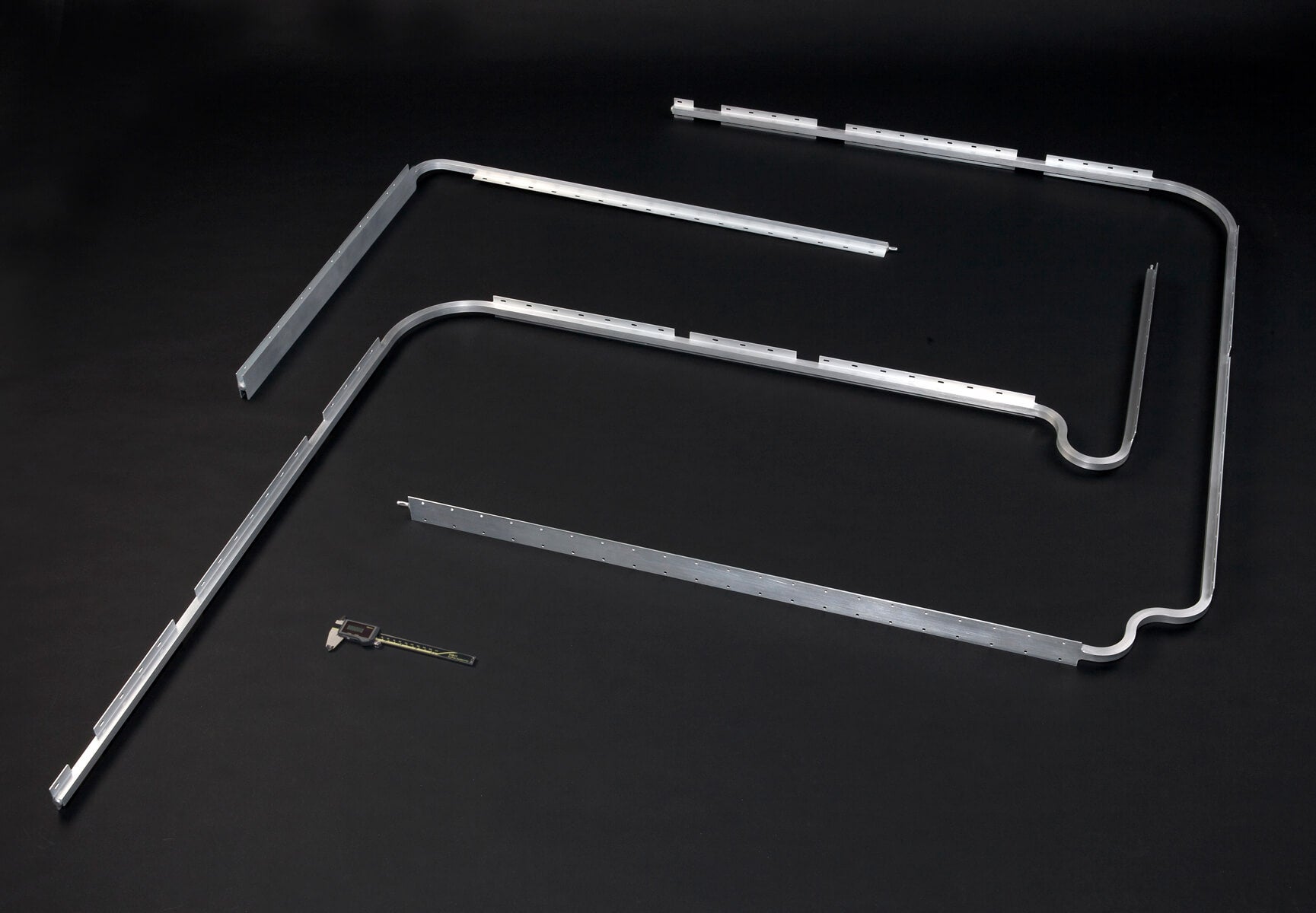

Passive two-phase technologies have long been an area of expertise for ACT. Heat pipes, HiK™ plates (high-conductivity plates with embedded heat pipes), vapor chambers, and loop thermosyphons are a few of the technologies that have been successfully designed and implemented in a wide range of markets and applications. With no moving parts, these technologies are especially favored in environments where maintenance is prohibitive, and reliability is paramount. Spaceflight has proven to be one such environment. In recent years, ACT has seen a rise in thermal demands for the burgeoning spacecraft industry. The company’s constant conductance heat pipes (CCHP) recently surpassed 66 million hours of spaceflight heritage, and in anticipation of an even greater need, ACT’s Lancaster facility underwent a 32,000 ft2 expansion to accommodate its CCHP production. Other technologies (e.g., space copper water heat pipes, variable conductance heat pipes, loop heat pipes, pumped fluid system accumulators) have supported such programs as NASA’s Nancy Grace Roman Space Telescope, Europa Clipper Mission, GOES-R Weather Satellite, VIPER Lunar Rover, DART Mission, and the International Space Station.

In addition to its passive solutions, ACT also employs active designs to cool high-power electronics in both industrial and military applications. In 2018, ACT acquired Parker Hannifin Corporation’s Precision Cooling Business, which designs and manufactures pumped-two phase (P2P) solutions. The acquisition enhanced ACT’s experiences in pump reliability, field installation, and service for this technology. P2P solutions are ideal for the cooling of high-power electronics where heat loads have increased to a level beyond what traditional air- and water-cooling systems can effectively manage. These solutions increase power densities for high-power electronics by more than twice as much as traditional water/glycol systems, and they utilize non-conductive fluid to ensure the safety of sensitive electronics in the event of an accidental fluid leak. P2P cooling is utilized in such applications as military equipment, industrial power electronics, alternative power generation, marine and rail propulsion, medical equipment, and data centers.

In March 2021, ACT further expanded its thermal management capabilities with sub-ambient options when it acquired the Tekgard® brand of military environmental control units (ECU) and chiller systems. Designed and manufactured at ACT’s York facility, Tekgard® products have served the military community with trusted thermal systems for over 20 years. These ECUs provide thermal support for military personnel and equipment housed in shelters, base camp facilities, command centers, and more. Unlike commercial HVAC equipment, ECUs are designed to perform in harsh conditions, and they are ruggedized to survive the rough terrain and environmental challenges the military faces in its operations. These solutions are also engineered for mobility and can be mounted to trailer systems for convenient towing. Fielded examples of Tekgard® ECUs have supported the Patriot Air and Missile Defense System FMS Cases, Terminal High Altitude (THAAD) Program, AN/TPS-77 Long-Range Radar System Program, Universal Ground Control Station (UGCS) Program, Standard Integrated Command Post System (SICPS) Program, and the Gray Eagle Unmanned Aircraft System (UAS) Program.

Likewise, Tekgard® chillers are ruggedized in a similar fashion; these systems provide fluid-cooling solutions for mission-critical equipment where overheating is a major concern. The sensitive electronics found in radar, missile-defense, and automated weapons systems are protected from overheating, ensuring their operability when their services are needed most. Tekgard® chillers have supported such programs as the Howler Counter-Drone System, the Ku-Band Radio Frequency System (KuRFS), and the Land-Based Phalanx Weapon System.

ACT, classified as a Small Business, is experienced in designing to mil-spec qualifications and has been ISO 9001: 2015 and AS9100 certified and ITAR registered. Between its Lancaster and York facilities, the company has 220 full-time employees and many part-time employees and consultants. ACT’s facilities total approximately 200,000 ft2 of combined office, laboratory, and manufacturing space, all of which is utilized to achieve its mission statement of becoming the best thermal management company in the world.