Services Should Share 3D Printing Information

Services Should Share 3D Printing Information

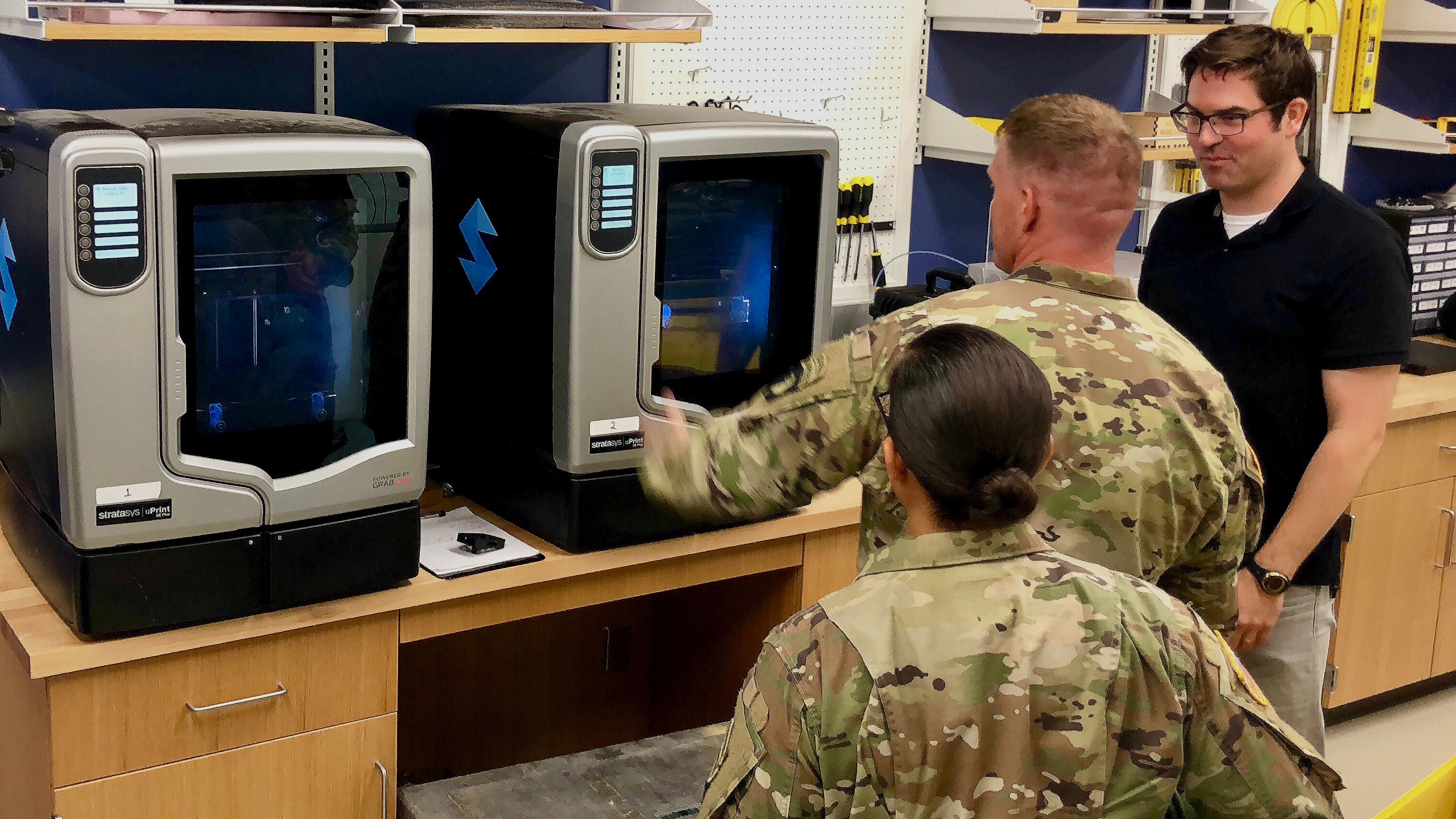

The Army and the other services have successfully used 3D printing technology to tackle the military’s parts and supplies shortfalls, but they should work to develop common standards so it’s easier to share their product specifications and needs, according to a new report from the Defense Department inspector general.

Known as additive manufacturing, the 15-year-old process allows on-the-spot replacement of nonrepairable or nonprocurable parts by making them. Examples of AM materials include plastics, metals and ceramics.

The process is gaining in the Army. As of February, at least 19 Army locations, including maintenance depots, engineering commands and deployed units, were using it to supplement the supply chain, according to the IG report.

The Army also has mobile labs deployable worldwide to support forward-deployed soldiers and has created containerized manufacturing labs that have accompanied units on major exercises.

So far, the Army has deployed the mobile labs to Germany, Thailand, Japan and South Korea, and Army policy allows commanders to determine which parts to produce using AM. Those items serve as a temporary replacement until the traditionally manufactured part arrives.

The Army describes this as a major leap forward in readiness, as AM technology can “improve the performance of Army weapon systems on the battlefield,” and give “the Army a tactical advantage by providing the ability to manufacture and produce items as close to the point of need as possible.”

Soldiers have successfully used AM for parts and tools to cut maintenance time and cost, according to the report. For example, soldiers designed and produced an AH-64D Apache helicopter strap pack support, a tool used by maintenance personnel to help uninstall and reinstall the rotor blades.

The tool, which took nine hours to produce and cost $3.21, saved 12.4 maintenance hours and $20,000, according to the report.

The Defense Department could grow the use of AM if it developed a way to standardize the process across the services, the IG concluded.

Currently, each service has its own process, procedure and system that lacks standardized data or cataloging, the report says. In March, DoD issued an interim policy asking for first steps to be taken to define roles and policies that could be shared across all branches.

Standardized equipment data allows the services to be aware of the location and type of AM equipment available. It could also increase the likelihood that a unit will use AM to produce a part, which would “reduce the cost and time for repairing some unusable equipment,” the report states.

Read the full report here.